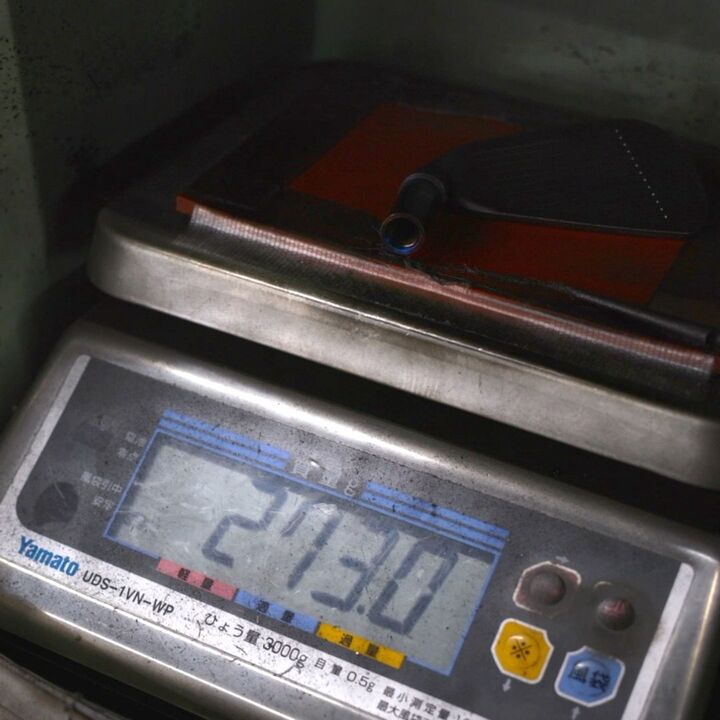

Blade & Hosel Grinding

An accurate top line is created during this step. Once the top line is complete, the grinding of the hosel follows. Since the player’s eye will move from the top line, to the hosel, and up the shaft—the grind must be precise. Each worker on the grinding line must ensure this stage is completed to perfection.

In order to reach this stage, the Miura factory has produced three individual sets of dies for each model and loft. Dies alone will not deliver a quality iron—each model needs a precise amount of heat and force. Forging also requires the skill, patience, and experience of a Miura craftsman.

Your Privacy Choices

Your Privacy Choices